CLIENT: Source Marketing for Cleveland Golf

PROJECT: Eco friendly golf club stand

PRODUCED: December 2023

VISIT: Cleveland Golf UK

Eco friendly stand case study

THE BRIEF

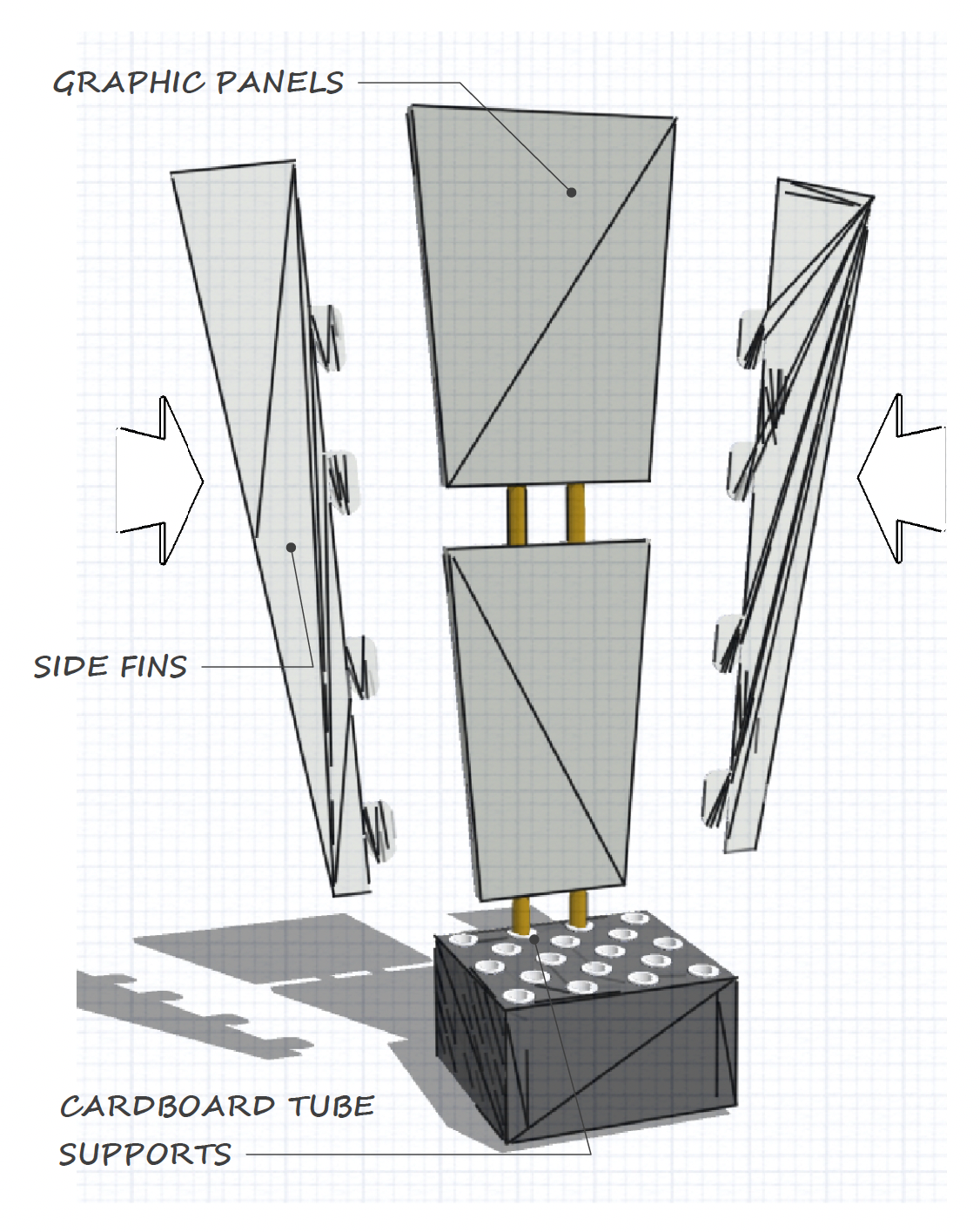

Create an eye-catching and carbon friendly point of sale golf club stand utilising an existing metal base unit to hold 18 clubs.

Use Eco friendly recyclable substrate that can be updated when new club models or promotions are launched, creating a reusable unit that benefits any updates. The new display unit must result in less future design, less future costs, less future distribution and less future waste.

To develop the design so it showcases the product to the maximum whilst ensuring stability and strength so it can be used safely within 'Health & Safety' regulations in a retail environment.

This was a project requested by one of our regular customers, who knew we would be able to develop the existing base unit into a completely new, long lasting and reusable display unit.

THE CONCEPT

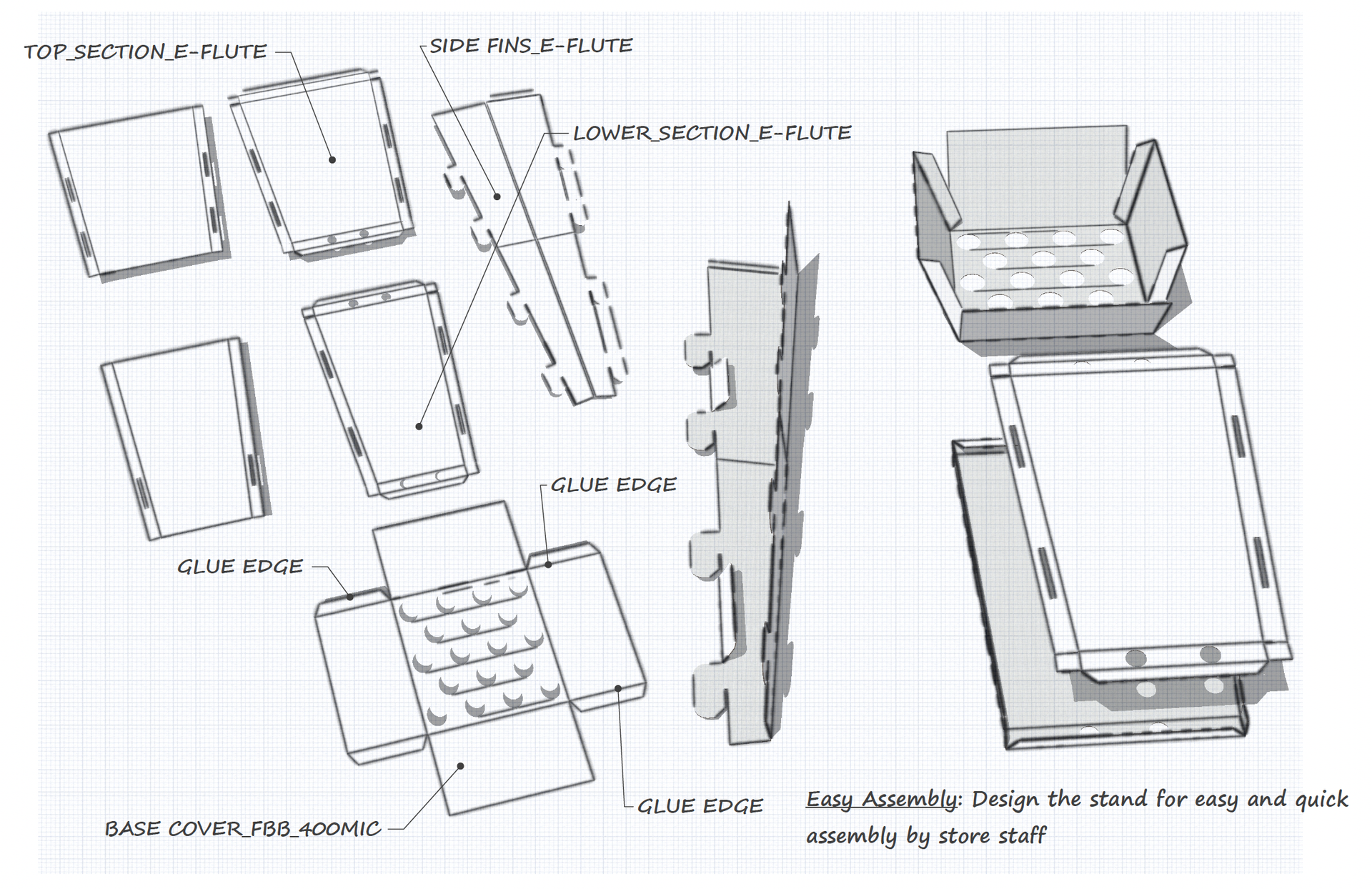

Internal design meetings with the project manager and design team were held to determine a cost effective and practical method of production that would meet our client's requirements. It also involved material trialling, suitability and cost effectiveness modelling.

During the design process there were stability issues and concerns regarding the best way to integrate the existing base with the new eco display unit. It involved testing that the unit withstood sudden blasts of air (if placed near a door) as well as the 'human factor' of shoppers handling the product in-store and the unit's stability and it's weight bearing capabilities. Several prototypes were developed and trialled, with improvements made on each occasion.

PROTOTYPES

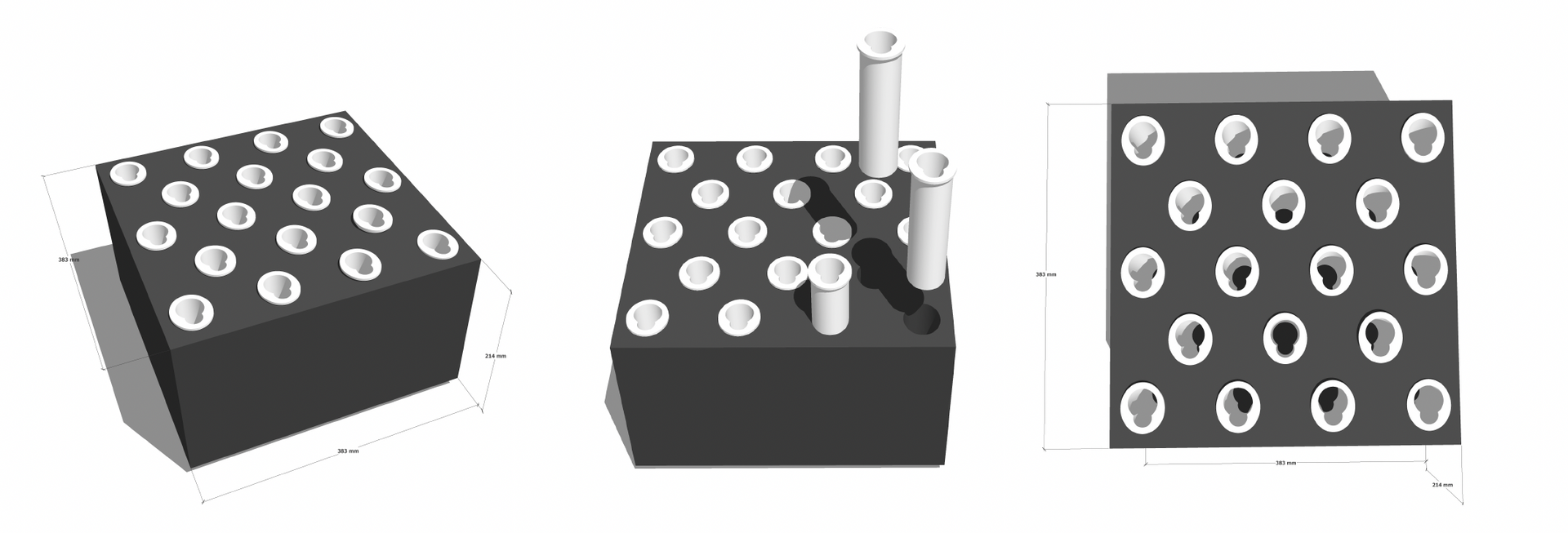

Once the initial design was agreed by all parties it was created by our creative 3D engineering department on the CAD system for a prototype to be made.

During the design process there were minor stability issues and concerns regarding the best way to integrate the existing base with the new eco display unit. It involved testing that the unit withstood sudden blasts of air (if placed near a door) as well as the 'human factor' of shoppers handling the product in-store and the unit's stability and it's weight bearing capabilities. Several prototypes were developed and trialled, with improvements made on each occasion.

PRODUCTION

After further testing, the customer passed a mocked up sample and the job went into full production, with an initial order of x300 units being made. These were successfully used in multiple UK and European sports shops.

Plans to re-use the base and produce a new promotion using the basic format of our research and development are in the pipeline. This project ticked all of our client's requirements of reusability and a healthy carbon footprint.